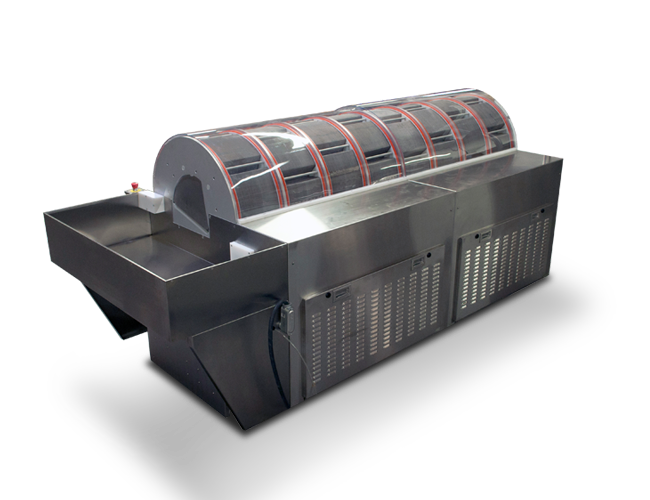

8 Basket Tumble Dryer

Providing Speed and Efficiency in the Gelcap Drying Process

GIC Engineering has developed the two most efficient, GMP designed, FDA validated tumble pre-dryers in the industry. Using the rotary basket, fluidized bed action of drying, our 5 and 8 Basket Pre-Dryers can dry capsules up to 20% w/w for even the highest output machines.

- Frame is 304 stainless steel welded elements with 304 stainless steel sheet metal skin

- GMP designed, FDA validated

- Shaft driven rotary basket design - no belts, chains or grease contamination

- Basket design - stainless steel construction, lightweight, easy to remove and clean. Empty weight of each basket is 10 kg

- High output centrifugal blower for increased air circulation and moisture removal

- Automatic product transfer doors with manual override - FIFO method

- Easy adjustable softgel dwell time in the baskets

- Designed for temperature sensitive softgels for drying with no thermal degradation due to rapid absorption of the latent heat of vaporization

- PID controlled air temperature

- Optional stand alone PLC, operator interface panel

- Capable of reducing capsule shell moisture content up to 20% w/w water

- Optional variable speed blowers and tumble motors

- Optional variable temperature adjustment for each basket

Power Requirements

- 208 / 220 / 460 V, 3 Phase, 60 Hz

- 380 V, 3 Phase, 50 Hz

Machine Dimensions

- 93" (L) x 44.5" (W) x 52" (H)

- 113cm x 236cm x 132cm

Fixed Machine Speed

- 42 rpm

Machine Weight

- 2000 lb (900 kg)

PID Controls

- Air Temperature

- Capsule Dwell Time

Combined Airflow

- 2000 SCFM