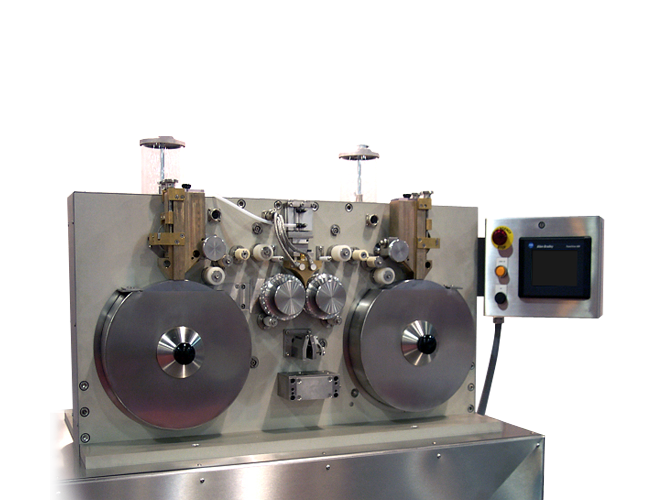

Benchtop Machine

Softgel Encapsulation Machine for Research and Development

With a space saving footprint of 3’x 4’, our innovative Benchtop encapsulation machine was the only one of its kind when first introduced in 2002. The development of the Benchtop machine has provided the research and development departments of pharmaceutical and nutraceutical companies with a low cost entry into the fastest growing dosage form in the industry. It enables these companies to bring softgel expertise in-house for cost effective product development. Using a 1.75" die roll, the Benchtop machine is capable of producing small quantities of capsules in a wide variety of standard sizes and shapes.

- Servo motor design

- Finest hardened tool steel construction with 304 SS casing

- Single dose medicine pump - capable of fill accuracy to ± 2%

- Die compression system for accurate, validatable, controlled die pressure

- Adjustable spreader boxes with thin ribbon capability - even ribbon thickness and controlled gelatin usage

- Pneumatic wedge lift system for accurate placement of die rolls

- Water cooled drums

- Set of standard shape and size die rolls with wedge

- Precise ribbon lubrication system - separate inside/outside ribbon lubrication

- Mangle roll and stripper brush assembly

- Stainless steel gelatin net receiver

- Electric control panel (optional PLC, operator interface, touch screen panel)

Die Rolls

- 4" diameter (102 mm) x 1.75" long (45 mm)

- Working width is 1.2" (35 mm)

Overall Machine Dimensions

- 24" (L) x 42" (W) x 42" (H)

- 106 cm x 61 cm x 61 cm

Pockets per Die, Standard Sizes

- 20 Oblong - 23

- 10 Oval - 22

- 7.5 Oval - 24

- 8 Oval - 28

Approximate Fill and Gelatin Usage (1rpm)

- 20 Oblong - 1 kg fill and 700 g of gelatin every 20 minutes

- 7.5 Oval - 0.2 kg fill and 700 g of gelatin every 20 minutes

Fixed Machine Speed

- Variable 1 rpm

PLC Controls

- Variable speed to 5 rpm

Machine Weight - 1200 lb (550 kg)

PID Controls for

- Wedge

- Spreader boxes

- Casting drums

Power Requirements

- 220 V, 1 Phase, 50/60 Hz

- 10 amps

- Chilled water

- 1 SCFM compressed air